Q 01: What is an electrical transformer?

Ans: A transformer is simple static electromagnetic passive electrical device that operates on the principle of Faraday’s law of electromagnetic induction in the form of mutual induction by converting electricity from one level to another. The induced electricity may involve changes in magnitudes of currect and voltage, although it’s always transferred without a change in frequency (Hz) and can be transferred from one circuit to another without actual contact. An electrical transformer must be supplied with an input source voltage that varies in amplitude as it operates on the pronciple of electromagnetic induction.

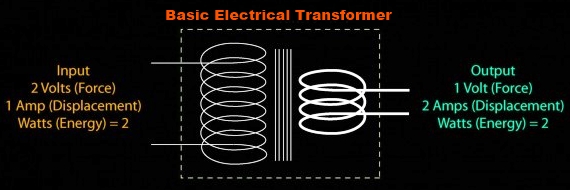

Q 02: How to explain the electrical transformer basic theory and principals of operation?

Ans: In a transformer circuit with the primary winding or coil is connected either to a high frequency or low frequency AC voltage power supply, the magnetic flux builds up and contracts about the primary winding or coil. The oscillating magnetic flux around the primary winding or coil cuts the secondary winding, and induces an alternating voltage into the winding or coil. This voltage causes alternating current (AC) to flow through the load. The level of alternating voltage may be stepped up or down depending on the relative orientation and windings ratio of the primary and secondary windings or coils. If the windings or coils of electrical transformer are wound in the same field, the induced voltages will be proportional to the number of turns in each winding or coil (Note: Visit here for more details about Working Principle of Transformer).

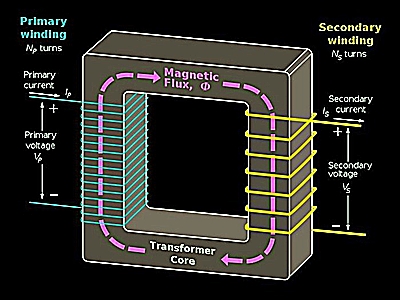

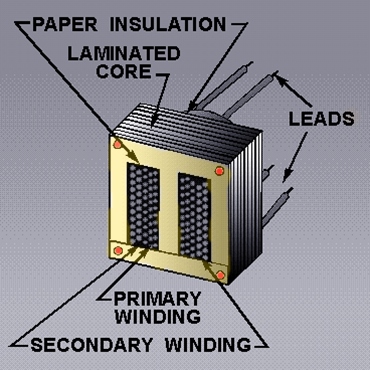

Q 03: What are the principle components of an electrical transformer?

Ans: In its most basic form, an ideal electrical transformer consists of a CORE (usually made of silicon steel laminations which are insulated from each other by a thin layer of coating) that supports the coils or windings and provides a path for the magnetic lines of flux, a primary coil or winding which receives electrical energy from the AC source, the secondary coil or winding which receives electrical energy from the primary winding and delivers it to the load, and the outer case (enclosure) which protects the above principle parts from physical damage and environmental effects.

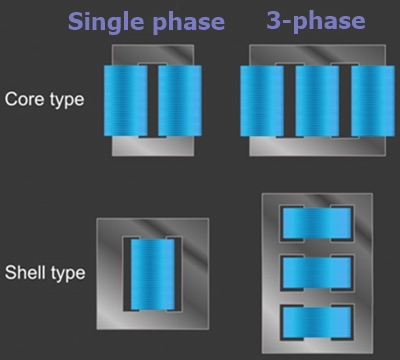

Q 04: Common constructions of a typical electrical transformer, what are they?

Ans: There are “CORE type” and “SHELL type” two common types of transformer construction. Both the primary and secondary coils or windings are constructed on the inner leg of a “SHELL type” transformer, whereas the primary and secondary coils or windings may be built on the separate legs of a “CORE type” transformer. Normally, an electrical transformer is designed so that the path of magnetic lines around the core is as short as possible (Note: a longer path or smaller cross sectional area requires more turns/volt and vice versa, and the number of turns required is inversely proportional to the cross sectional area of the transformer core).

Q 05: Are there any differences between a voltage transformer and current transformer?

Ans: Both voltage transformer and current transformer are typically made of cores with windings or coils. In theory there is no difference between these types of transformer, but the voltage transformers are operated at much higher magnetic flux, whereas the current transformers are operated at a lower flux so that the magnetizing current will be just small portion of the output alternating current (AC).

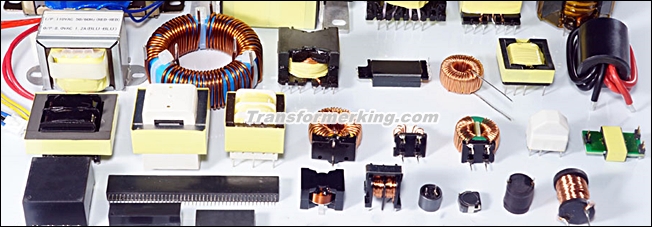

Q 06: What are some of the primary types of electrical transformer available in the global market?

Ans: Transformers can be classified in different ways, depending upon their application, function, design, type of cooling employed, size or shape, etc. For examples, electrical transformers can be categorized as “Core- type Transformer” (the windings are given to a considerable part of the core) and “Shell-type Transformer” (the core surrounds a considerable portion of the windings) according to the design. Also, electrical transformers can be categorized as “Oil filled self-cooled type”, “Oil filled water cooled type”, and “Air blast type” base on the type of cooling employed. Some of the common types of electrical transformer in use today are listed below:

(1) Power transformers: For use in power electricity transmission network.

(2) Instrument transformer: For use in different equipment and devices in the electrical and electronics industries.

(3) Pulse transformer: It is not designed for power conversion, but optimised for transmitting rectangular electrical signals or digital pulses with quick rise and fall times which are coupled with relatively constant amplitudes.

(4) Radio Frequency (RF) transformers: Four examples of RF transformer are the “Air-core transformer” used for high frequency work, “Ferrite-core transformer” used for intermediate frequency work, “Transmission-line transformer” for radio frequency use, and “Balun transformer” used to connect between balanced and unbalanced electrical circuits. A broadband RF transformer is designed to provide an impedance transformation over a wide frequency range.

(5) Audio frequency transformers: For use in audio circuits to carry audio signal over the audio frequency range (i.e. the full audio range is 20 Hz to 20 kHz).

(6) Miscellaneous electrical transformer types.

Q 07: Does TransformerKing manufactures custom transformers (i.e. high quality custom made transformers built to specifications & customer requirements)?

Ans: TransformerKing can design and manufacture a wide range of custom transformers which are high quality and cost effective specifically to meet the needs of our individual customers. No matter what your transformer needs are, TransformerKing can help you design & custom made good quality electrical/electronic transformers for your business. We can help you select, design and build a wide range of the electronic/electrical transformers manufactured in accordance to the CE, UL, European, Canadian electrical code requirements.

Q 08: Is TransformerKing an ODM company for electrical & electronic transformers?

Ans: Yes, TransformerKing is an original design manufacturer or ODM company that designs & manufactures both standard and custom transformers used in the power supply, PV solar energy, telecommunication, sound & audio, LED lighting, marine, automated production equipment and various other industries. Our highly experienced transformer designers & engineers not only can accommodate your special transformer design requests, but also can assist you in custom transformer design so as to meeting your exact ODM transformer specifications.

Q 09: Does TransformerKing offers OEM manufacturing of electronic & electrical transformers?

Ans: TransformerKing can produce high quality & cost effective OEM transformers for our valuable customers worldwide in the power supply, solar power, telecommunication, audio & sound, marine, LED lighting, automated manufacturing machinery and various other industries. Our company can help you in your specific contract manufacturing requests for electronic/electrical OEM transformers.

Q 10: Is there a minimum order requirement for the ODM or OEM transformers manufactured by TransformerKing?

Ans: Normally there is no minimum order requirement for our OEM or ODM transformers, but we do request that our customers commit to a minimum order quantity of transformers that can be produced & shipped over within an agreed-upon time schedule and payment terms. Our company can cope with specific ODM or OEM requests for small to large volume electrical or electronic transformers.

Q 11: What makes TransformerKing stand out from many other transformer suppliers, manufacturers and competitors in China as well as overseas?

Ans: TransformerKing is able to propose a quotation that shows what is possible in terms of imposing no minimum order quantity (MOQ) on your purchase order for our electrical & electronic transformers, and to accept the purchase orders for small to large volume of custom made transformers. Besides, TransformerKing is highly experience in the design, manufacturing and supplying of high quality standard transformers and custom transformers at competitive prices. We’re doing our transformer business with an open, honest and transparent attitude, thus you’re welcome to discuss your OEM/ODM transformer requirements and cost issues with our senior transformer designers and specialists so as we can assist you with your needs to stay above the competition in your transformer business. Finally but not least, we are always looking for approaches to enhance the lead time (LT) and cost on our transformers (i.e. we are capable of producing & delivering electrical/electronic transformers with shorter lead times and competitive prices to our local as well as overseas customers).

In short, the TransformerKing’s company strength regarding electronic & electrical transformers sourcing and manufacturing are listed as follows.

- Have no MOQ.

- Have short Lead Times (i.e. LT of about 2-3 weeks or even 1 week).

- Can provide locally sourced magnetic raw materials (e.g. core, bobbin wires, tapes, and other raw materials for magnetic).

- Comprise of highly experience technical personnel who are previously working for Delta and Pulse the leading electrical transformer manufacturers in China.

- Capable of producing and supplying electrical/electronic transformers which are in compliance with the CE, UL, CSA, TUV, Insulation System Certifications (Class B, Class F, Class H and Class N), REACH and RoHS standards and requirements.

Q 12: Can TransformerKing supply OEM/ODM high frequency transformers built to customer specifications?

Ans: Yes, the TransformerKing can custom design, manufacture and supply a wide range of good quality & low-cost high frequency transformers per our customer requirements and specifications in China and overseas (e.g. in Japan, North America, Europe, Middle East and many more). There is normally no minimum order quantity (M.O.Q) for our high-frequency transformers in which our company accepts small to large volume product orders of high frequency standard transformer and high frequency custom transformer.

Q 13: Are lowering your transformer costs important to your business?

Ans: Please let us review your standard or custom transformer requirements/specifications so as we can suggest on the cost effective transformer solutions which might help you to do even better. Our years of experience and good knowledge in the production of reliable & affordable ODM & OEM transformations have helped many businesses in the same situation in the America, Canada, Europe, Australia, Singapore, etc.

Q 14: Does TransformerKing offers OEM product sourcing services?

Ans: YES, we do offer the sourcing services for a wide range of OEM transformer products in China for buyers from the North America, South America, EU and other European countries, the middle-east and Asian countries. Please feel free to contact us via the Online Enquiry Form or give us a call for your enquiry about the OEM transformer sourcing services offering by TransformerKing.com.

Q 15: Can company logo or trademark of our customers be put on the ODM/OEM transformers manufactured by TransformerKing?

Ans: OEM transformers produced by TransformerKing are without our company logo or trademark, therefore our transformer customers can request for their company logo or business trademark to be added on the OEM/OEM transformers we manufactured for them.

Q 16: What are the nearby international airports to our transformer factory location in the Guangdong province of China?

Ans: We welcome all our perspective customers to visit our transformer ODM/OEM manufacturing plant in the Dongguan City of China at anytime (click here for office location maps). It is very convenient for visitors travelling to, or from, our location through the Hong Kong International Airport (HKG)(estimated driving distance is 62 miles / 100 km), Shenzhen Baoan International Airport (SZX)(43 miles / 70 km), and Guangzhou Baiyun International Airport (CAN)(53 miles / 85 km). Hong Kong transport connection with the mainland China (by sea ferry, road coach and SkyLimo services) is also available.

Q 17: How to find reliable overseas manufacturers in China (e.g. TransformerKing.com) to produce your custom OEM/ODM transformer products?

Ans: You can use the major search engineers like Yahoo.com, Google.com, Bing.com, Baidu.com and so on, or through a trusted buying agent in China. Please visit TransformerKing.com our company website for details on how we can help to manufacture ODM/OEM transformer products in China per your product specifications.

Q 18: Is it important to find an ODM/OEM transformer contract manufacturer in China who can communicate with you in English and/or native Chinese languages?

Ans: We believe that effective communication is the key to international trade. So, if you would like to outsourcing the manufacturing of your transformer products overseas in China, just make sure your company has found a China OEM/ODM transformer manufacturer who speaks both English and the native languages. At TransformerKing, both our sales manager and chief design engineer for electrical transformers have the ability to speak, read and/or write in English and a variety of China mainland’s local dialects (local spoken forms).

Q 19: Does TransformerKing respect confidentiality in business and the intellectual property rights of our ODM/OEM transformer customers?

Ans: Ethical dilemmas may occur when values are in conflict, but we at TransformerKing recognize the importance of confidentiality in business and intellectual property rights related to OEM/ODM transformers. Yes, we do RESPECT for intellectual property and our valued customers, thus we will not to disclose any Confidential Information of our valued customers to 3rd parties and to use the ODM/OEM transformers contract manufacturing information solely for the purpose described in Non-Disclosure agreement (NDA), Proprietary Information Agreement (PIA), Confidential Disclosure Agreement (CDA), or Confidentiality Agreement (CA).

Q 20: What about shipping and exporting of ODM/OEM products and components?

Ans: TransformerKing doesn’t offer shipping and exporting services, but we can help our customers to find reputable shipping companies or exporting agents in China / freight forwarders in Hong Kong to take the complete responsibility of shipping OEM/ODM electronic & electrical transformers from China to about anywhere in the world (e.g. to the US and Canada in North America, EU and non-EU countries in the Europe, middle-east and southeast Asian countries, and so on).

Q 21: Who is responsible for replying the request for quotations of ODM or contract manufactured transformers at the TransformerKing?

Ans: If you have any enquiries or would like a quotation for our ODM/OEM transformer manufacturing services, Please email us your request for a transformer quotation (RFQ). We at the TransformerKing.com will be able to reply you very quickly from a few days to 1-2 weeks depending on the magnitude of your enquiries or RFQ.

Q 22: What is the significant of a Conformite Europeene (CE) marked transformer?

Ans: Certain categories of electrical and electronics products must have a CE Mark to be legally placed and sold on the markets in the EFTA and European Union (EU). TransformerKing is an OEM/ODM manufacturer of CE marked transformers that we can design and manufacture standard & custom CE marked transformers which are in conformation with the EN 61558 Standards and diversely catered to European countries (e.g. UK, Germany, France, the Netherlands, etc.). You can visit the CE official website to find out whether your ODM/OEM transformer products require CE marking.

Q 23: What does the UL marking on an ODM/OEM transformer product mean?

Ans: UL Mark on an OEM/ODM transformer implies the Underwriters Laboratories (UL), a not-for-profit organization, has evaluated and tested representative samples of that OEM/ODM electronic/electrical transformer for safety risks, and certified that they comply the excellent standards and safety requirements of the UL.

Q 24: What do the EU RoHS Marks or Ratings mean to our electrical & electronic transformer customers?

Ans: The EU Restriction of Hazardous Substances (EU RoHS) Directive restricts the use of certain hazardous substances in the electrical and electronic products on sale in the EU. Any EU RoHS compliant electrical transformer product is tested for the presence of lead (Pb), cadmium (Cd), mercury (Hg), hexavalent chromium (Hex-Cr), polybrominated biphenyls (PBB), and polybrominated diphenyl ethers (PBDE).

Q 25: What is the Quick Response (QR) Code for TransformerKing.com?

Ans: The QR Code for TransformerKing.com is shown below. Such a scannable matrix barcode (e.g. scan with a cellphone or digital scanner) is processed using Reed-Solomon error correction until the 2D barcode is interpreted correctly. Information in a form of digital data is then extracted from the black square dots display in both vertical and horizontal components of the 2D barcode.

Last Updated: 20-09-2016